You have no items in your shopping cart.

Building Strong Foundations in

5000+ Cost-Effective Projects

Explore DiamondGrid™'s legacy of success — chosen for over 5000 cost-effective projects. As a reliable steel reinforcement alternative, DiamondGrid™ ensures ground stability and unmatched savings in every endeavor.

7000tonne/m2

Filled Crush Resistance

filled with concrete

DiamondGrid™ transforms your projects, providing unparalleled support even under the heaviest loads, whether in construction, mining or agriculture.

300tonne/m2

Empty Crush Resistance

Versatile strength at 300tonne/m2. DiamondGrid™ provides unwavering support for various projects, ensuring resilience in every application.

Up to 91%

Less Concrete

Cut concrete costs by up to 91%, making DiamondGrid™ a superior alternative to traditional steel reinforcement methods.

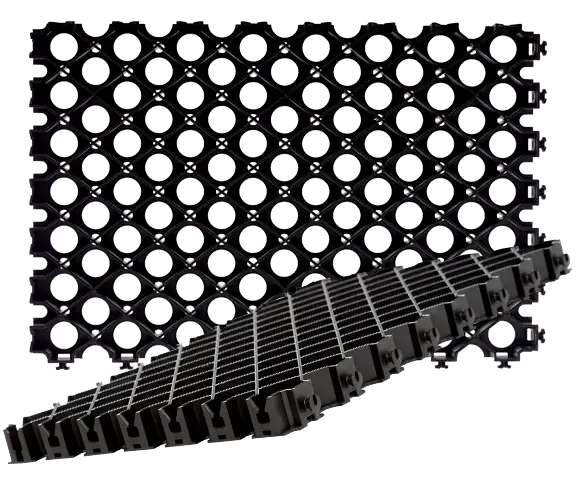

Easy to install

with interlocking system

DiamondGrid™'s interlocking system is robust and easy to install, ensuring confidence in every construction endeavor.

Why Use DiamondGrid™?

Innovative Engineering, Unrivaled Strength

Imagine a sub-terrain grid system that's light, robust, and resilient, offering an innovative solution for concrete reinforcement and ground stabilization. After rigorous research and testing, DiamondGrid™ emerged as the alternative that exceeds expectations.

Even Load Distribution

Achieve balanced load distribution, mitigating stress points and prolonging infrastructure lifespan.

Increased Traffic Capacity

Expand traffic capacity without adding pavement thickness, accommodating growing demands with existing infrastructure.

Enhanced Load Capacity

Boost road load-bearing capability, ensuring infrastructure can withstand heavier traffic and loads with confidence.

Extended Road Lifespan

Maintain road integrity over longer periods, reducing repair frequency and ensuring sustained functionality.

Drastic Maintenance Cost Reduction

Slash maintenance expenses by up to 70%, optimizing operational budgets while ensuring long-term road reliability.

Cost-Effective Subgrade Preparation

Reduce preparation costs by minimizing required thickness, optimizing budgets without compromising quality.

Streamlined Vehicle Accessibility

Expedite vehicle travel times, optimizing logistics by enabling faster point-to-point transportation, reducing personnel and vehicle requirements.

Improved Safety and Efficiency

Enhance safety and fuel efficiency by eliminating hazards like potholes and corrugation, promoting smoother, faster, and safer travel.

featured projects we supplied

Where Strength Meets Sustainability

Explore how DiamondGrid™ is the ultimate alternative for various applications, demonstrating its adaptability in reinforcing concrete and ensuring stable ground conditions.

technical benefits

DiamondGrid™ vs Comparable Surface Solutions

| |

product specifications

Discover DiamondGrid™'s Engineering Insights

| specifications | |

|---|---|

| Dimensions (W x L x H) |

900mm x 560mm x 40mm |

| Crush Resistance (filled with concrete) |

7000+tonne/m2 |

| Crush Resistance (empty grid) |

300+tonne/m2 |

| Weight per grid | 3.2kg |

| Fill ratio | 1m3 of fill per 26m2 |

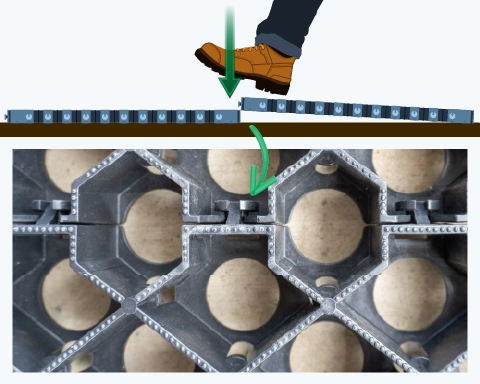

how to install

Easy Installation for DIY Success

Experience easy installation with DiamondGrid™'s robust interlocking system. Empower your projects and reinforce with confidence.

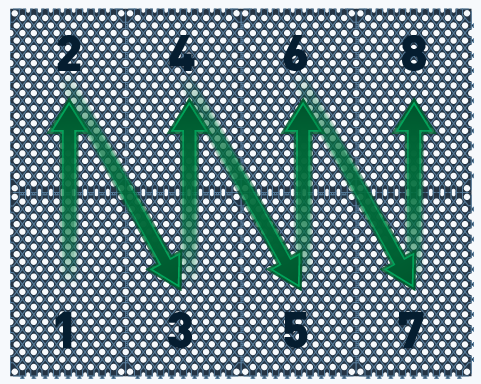

Lay the DiamondGrid™ grids, starting in one corner with male lugs facing outwards. Depress each connection until flat and secure.

Position the grids along the grooves, ensuring each piece securely interlocks with the next. Work methodically, aligning and connecting the grids to form a stable surface

Fill the DiamondGrid™ using a Bobcat and spreader bar or similar equipment with concrete for optimal stability.

frequently asked questions