You have no items in your shopping cart.

Enquire Now

Thanks for your enquiry

Thanks for your quote. We will be in touch as soon as possible.

Jointflex® is a closed cell, cross linked, non-absobent polyethylene expansion joint fillerboard for use in expansion and isolation joints in concrete and masonry structures. Jointflex® is non-absorbent and has excellent properties allowing it to be used in water retaining and excluding structures where potable, salt, chlorine and sewerage water is present.

Jointflex® has no bitumen content and joint sealant can be directly applied on top of it without the use of bond-breaker tape. Jointflex® is available in standard 50kg/m3 (low) density and also available in custom densities of 100kg/m3 (medium) and 150kg/m3 (high).

Supplied in sheet form and at a thickness to suit the joint width or can be custom cut in sheet sizes to suit the concrete thickness or width. Also available upon request with a tear-off cap to suit the joint sealant application depth.

Advantages:

- Non-absorbent

- Lightweight

- No bitumen contents

- Ability to compress and recover

- Non-extruding from joint movement

- Suitable for submerged or trafficable joints

- Durable

Areas of Application:

- Slab on ground

- Brickwork and blockwork

- Reinforced concrete structures

- Concrete roads and pavement

- Suspended slabs

- Basement and tunnels

- Water retaining/excluding structures

- Dams and reservoirs

- Bridges and viaducts

- Airport aprons and taxiways

Available Sizes:

- Standard sheet size 2m (L) x 1m (W)

- Density: 50kg/m3 (low), 100kg/m3 (medium) and 150km/m3 (high)

- In thicknesses of 10, 12, 15, 20 and 25mm. Sizes from 3mm - 50mm are cut to order

- Custom sizes available to suit

- Available with a tear off cap for easy joint sealant installation

Physical Properties - for 50kg/m3 Density

| Property | Method | Unit | Result |

|---|---|---|---|

| Density | ISO 845 | Kg/m3 | 50 |

| Tensile Strength: longitudinal | ISO 1798 | Mpa | 0.44 |

| Tensile Strength: transversal | 0.33 | ||

| Elongation at break: longitudinal | ISO 1798 | % | 100 |

| Elongation at break: transversal | 125 | ||

| Compression stress strain at deflection: 10% | ISO 3386 | KPa | 34 |

| Compression stress strain at deflection: 25% | 59 | ||

| Compression stress strain at deflection: 50% | 125 | ||

| Tear Strength: longitudinal | DIN 53507 | N/mm | 1.0 |

| Tear Strength: transversal | 1.1 | ||

| OPERATING TEMPERATURE RANGE: | |||

| Bending Test | Din 51949 | °C | -40 |

| Dimensional Stability | Din 53431 | °C | -40 |

| Compression set (22h, 25%, 23°C) after compression release: 0.5h | ISO 1856 | % | < 14 |

| Compression set (22h, 25%, 23°C) after compression release: 24h | < 6 | ||

| Thermal Conductivity at 0°C | DIN 52612 | W/mK | approx. 0.043 |

| Thermal Conductivity at 23°C | approx. 0.047 | ||

| Thermal Conductivity at 40°C | approx. 0.050 | ||

| Water absorption aftr 28 days | DIN 53433 | Vol % | < 3 |

| Water vapour diffusion resistance | DIN 52615 | 1 | > 3700 |

| Water vapour transmission rate 10mm | DIN 52615 | g/m2d | < 1.1 |

| Water vapour permeability | DIN 52615 | ng/Pa s m | < 0.078 |

Typical Applications

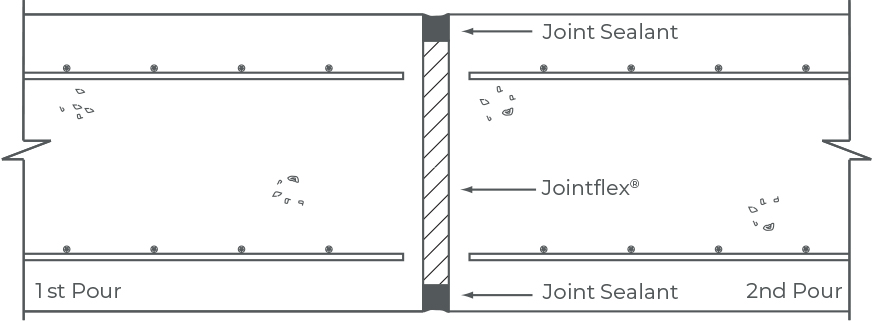

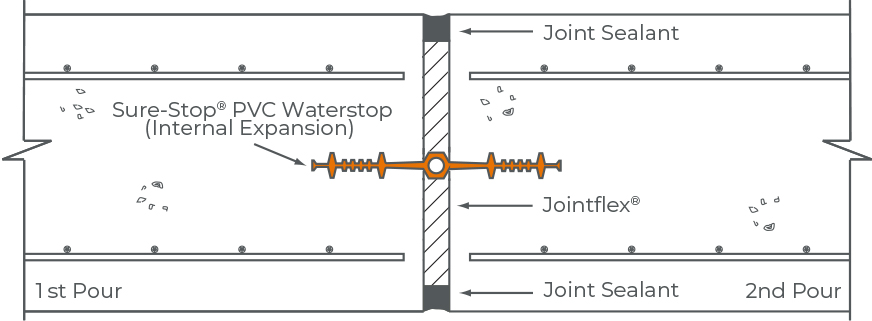

Standard Details of Wall Applications

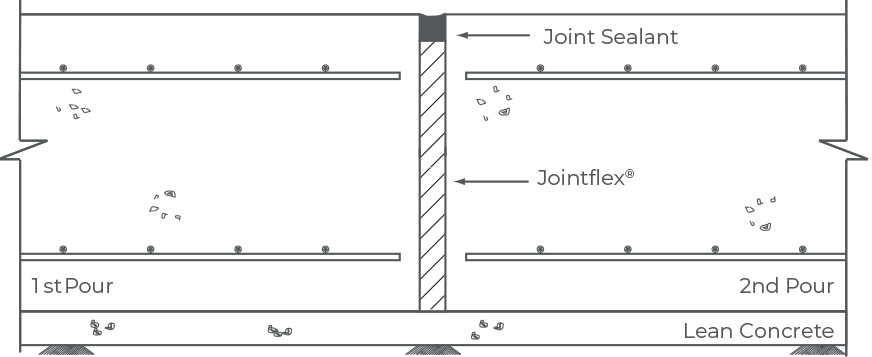

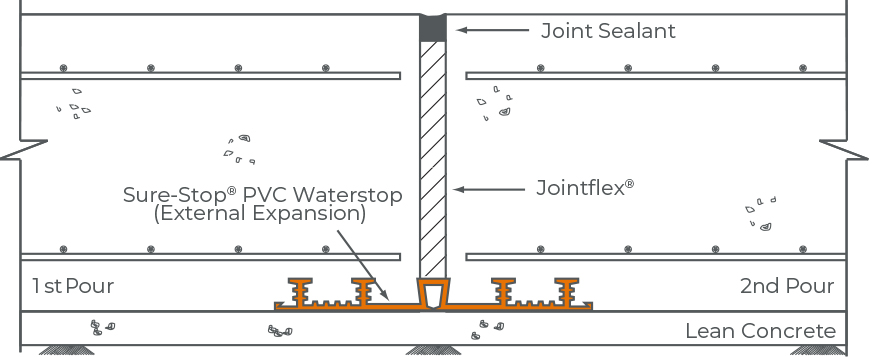

Standard Details of Ground Slab Applications

Installation Procedures:

Jointflex® is cut to size from sheets with a sharp retractable blade and adhered to the first concrete structure by a contact adhesive. Adhesive is applied directly to the Jointflex® in 50mm diameter ‘spots’ @300mm centers (approximately) or as required. Also refer to our installation method, available upon request.

Written Specifications:

Where shown in the drawings, the expansion joint fillerboard shall be Jointflex®, closed cell/cross-linked polyethylene fillerboard material, with a minimum density of 50kg/m3, as supplied by Corkjoint. The application / installation of the product must be in accordance with the manufatcurer’s recommentations.

Health and Safety Information:

For further information or advice on health and safety precautions, safe handling, storage and correct disposal of products, please refer to the most recent product Safety Data Sheet (SDS), which is available upon request.

| Dangerous Goods | No |

|---|---|

| Bulky Items | N/A |

| Wiise Seen | N/A |

| Unit of Measurement | No |

| Brand | No |

| Allow Rewards | No |